top of page

Skutro

A push n kick trolley with rider platform

Godrej Skutro

Godrej Skutro is a push-kick trolley specially designed to support the labour intensive tasks while picking an item inside a warehouse. Godrej being a leader in warehouse solution space was looking to solve the problems inside a warehouse and PencilProto get along with Godrej on this journey. PencilProto was able to realize the dream by placing effective design solutions on the table. Skutro was designed to be sold on e-commerce website and hence delivered to customers in a flat-pack corrugated box and also easy to deploy without any help of a service person. The design was loaded with end to end features which minimizes the user effort and validates cost to value factor. Skutro is designed to appear young, simple, mechanical and sturdy. PencilProto supported Godrej on this project from the sketch on paper till mass production and thus build a long lasting trust with the client.

Services

Research

Prototyping

User Experience

Industrial Design

Engineering Design

Packaging Design

New Product Development

Visualization

Research and Idea

In a normal day, a worker/picker travels about 10 km in a warehouse. These pickers work relentlessly to meet their target. But the tasks included are quite tiring to them and sometimes they are not even able to complete their target. So, there is a need/gap to fulfil the demand from picker's perspective yet could be less tiring while meeting a daily target. So we find a gap in such case and worked upon it. There are multiple possibilities when it comes to fill the gap. But the main aim was to find the right solution which could cater the need of a customer and also easy to manufacture and hence the birth of Skutro happens.

Industrial Design and Prototyping

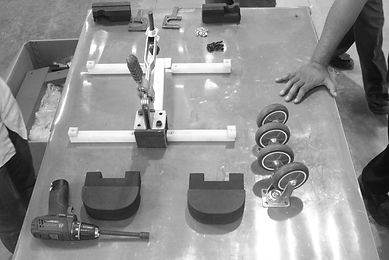

Prototyping is the core of new product development and PencilProto team proactively like to work on prototype which communicates effectively about the design feasibility. We built the first prototype to check the maneuverability of a trolley by adding a rider platform to it. Outcome of first prototype was implemented as one more iteration in design thus refining the design before working ahead on pilot launch. Team works relentlessly on the pilot launch and prepared ten working products so to send to various vendors across pan India. Final feedback of those vendors are then inculcated into final product before the launch.

Developing a better product

At refinement stages, Team realized that the maximum load is coming on four wheels. Since this product belongs to Godrej Material Handling divison, Skutro got its new look as Two forks at front than the traditional complete solid platform. Also by doing so, it is easy to flat pack the design and hence can be easily deployed across pan India. This gives a unique and distinctive look to Skutro. The material was modified to Aluminum because of less strength to weight ratio.

Water bottle holder

Brake

Extendable arm

Branding / Support plate

Castor wheel - Swivel

Rendered image of final production ready Skutro

Castor wheel - Fixed

Bell

Soft grip

Refinement, Packaging and Production

Each part of Skutro takes a complete refinement from production point of view. Below images present the step by step evolution happened during design process. PencilProto proposed mulitple options for packaging and final three options are made in 1:10 scale mockup. Final selected design for packaging and user manual is carefully selected and then proposed to Godrej management. PencilProto collaborated at each and every step of production till final product is ready for shipment to its valued customers.

Marketing Video

Marketing Banner

Want to transform an Idea into a product,

Let's discuss.

bottom of page